How does screen printing work?

Throw on your apron because we’ve broken down the lengthy process into 5 steps!

Shoutout to llaollao for showing off their t-shirts in production.

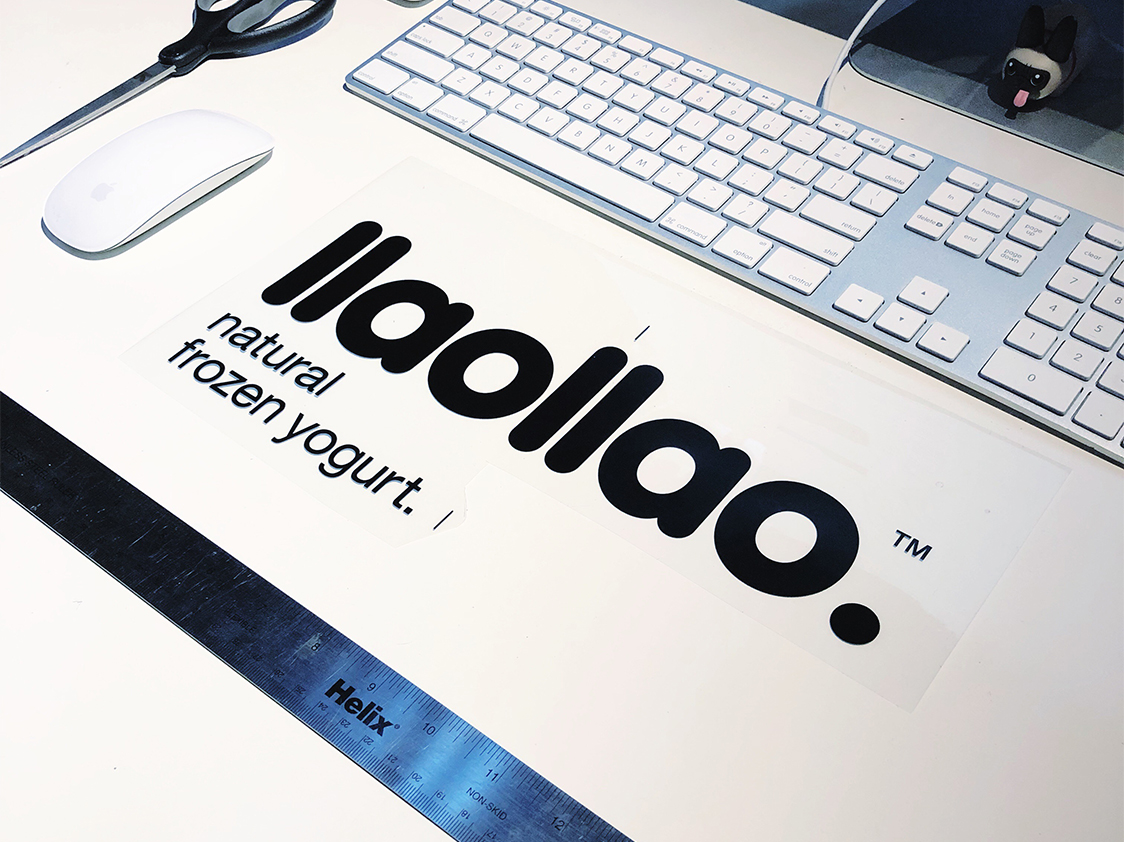

Step 1: Your Artwork

We prep your design on the computer and print it on a transparency with black ink. See those vertical tick marks on the transparency? That helps us center align your artwork on your shirt when it’s time to print. Even if your design is printed in color, the transparency must be printed in 100% black for dark room purposes in the next step. The color comes in later!

Step 2: Screen Prep

It’s time to move into the dark room. We take a mesh screen and coat it in a light-sensitive emulsion. This must be done in the dark or around a yellow tinted light (the yellow tint doesn’t effect the sensitivity of the emulsion, hence the yellow-tinted photo. Cool right?) After we let the emulsion dry (again, in the dark) we lay your transparency on the screen using a ruler to make sure it’s right in the middle. It’s then put on a light table where it’s exposed to a UV light for a few minutes. After that, we use a pressure washer to wash the screen. All areas of the screen that didn’t pass thru the light (your design) washes out.

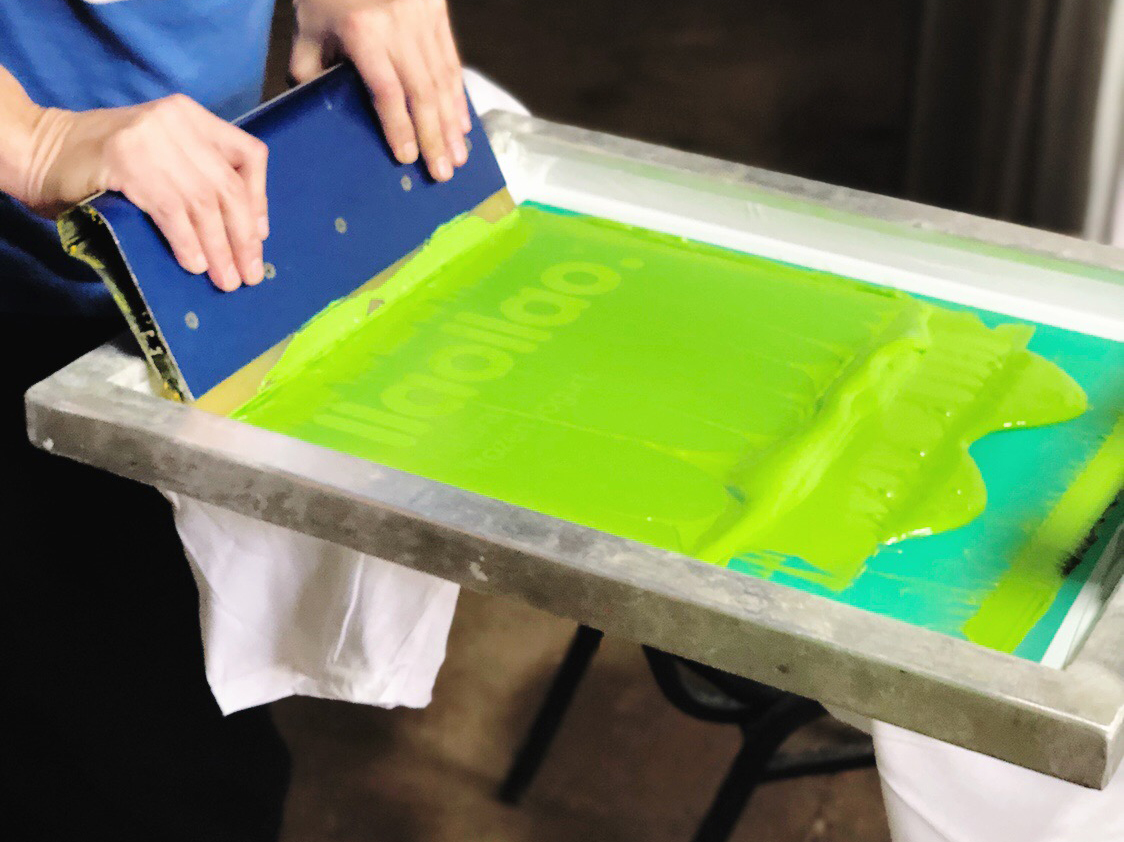

Step 3: Press Setup

After bathing in the sun to dry, your screen then moves over to the press and gets hooked into an arm, center aligned, and taped up on the edges. This is where we also mix the colors in your design and spread the ink onto the screen. The color we used for llaollao is Pantone 375.

Step 4: Finally, Time to Print

A shirt is placed onto a board sprayed in adhesive to make sure your shirt stays put. The screen is then lowered onto the shirt and ink gets spread across using a squeegee.

Step 5: Drying the Ink

After we pull the shirt off the board, we lay it on a conveyor belt that takes it into a 330 degree oven. It’s like a pizza oven, minus the pizza. Fun fact: the ink used on this order will never dry until it hits 330 degrees! That means we can leave it out in the open forever. Once it comes out on the other end, it’s packed up in a box and ready to wear!

And there you have it! Screen printing in 5 steps. Every t-shirt order that comes thru our door is unique so what’s not shown here includes multi-color designs, finishing options like foil, and much more. We take attention to detail seriously and that’s what makes a great quality product.

Do something awesome today,

APDAT Print Co.